Failing to sufficiently control for temperature can put mechanical stress on the board, which can lead to cracks and loss of conductivity. Proper temperatures are very important during the wave soldering process. The PCB then receives a water spray or air blowing to safely cool it and fix the parts in place. A pump in the pan creates a “wave” of solder that washes over the board, soldering the components to the board. It works by passing each circuit board over a pan of molten solder. Wave soldering is a bulk soldering process that enables one to manufacture many circuit boards in a very short amount of time. Reflow Soldering | More on Soldering and Printed Circuit Boards Jump To: What Is Wave Soldering? | What Is Reflow Soldering? | Wave Soldering vs. What is the difference between the two, and how do you know which type of soldering to use in which circumstances? There are two main types of soldering for PCBs: wave soldering and reflow soldering. But not all types of soldering are created equal, and it can be important to differentiate between wave and reflow soldering. Without soldering, there are no printed circuit boards. The only reliable way to get your circuits to stick to your board and stay there is by soldering them on. The cooling rate of the cooling section is generally 3~10☌/S, and it can be cooled to 75☌.Soldering is a huge part of the printed circuit board design process. In the case of the end, it can cause poor soldering and weak solder joint adhesion. Slow cooling will cause more decomposition of the circuit board into the tin, resulting in dull and rough solder joints. It should be cooled as fast as possible, which will help to obtain bright solder joints with good appearance and low contact. In this paragraph, the lead-tin powder in the solder paste has melted and fully wetted the surface to be connected. Temperature setting method of the reflow oven cooling section: The ideal temperature profile is the small volume covered by the "end zone" that exceeds the melting point of the solder.Ĥ. For 63Sn/37Pb solder paste with a melting point of 183☌ and a melting point of 179☌ For Sn62/Pb36/Ag2 paste soldering, the peak temperature is generally 210-230☌, and the reflow time should not be too long to prevent adverse effects on SMA.

#Solder reflow temperatures plus

Generally, the recommended solder paste is the melting point temperature of the solder paste plus 20-40☌. In the reflow section, the peak soldering temperature varies depending on the solder paste used. In this area, the heater temperature is set high, so that the temperature of the component rises rapidly to the peak temperature. The temperature setting method of the reflow section of the reflow oven: At the end of the heat preservation section, the oxides on the pads, solder balls, and component pins are removed, and the temperature of the entire circuit board reaches equilibrium.ģ. Give enough time in this area to make the temperature of the larger component catch up with the smaller component, and to ensure that the flux in the solder paste mixer is fully volatilized. The main purpose of the heat preservation section is to stabilize the temperature of each element in the SMA and minimize the temperature difference. The heat preservation section of the reflow oven refers to the area where the temperature rises from the melting point of the solder paste from 120☌ to 150☌. Temperature setting method of reflow oven insulation section: The typical temperature rise rate is 2☌/S.Ģ.

However, the ascent rate is usually set to 1~3☌/S. To prevent thermal shock from damaging the components.

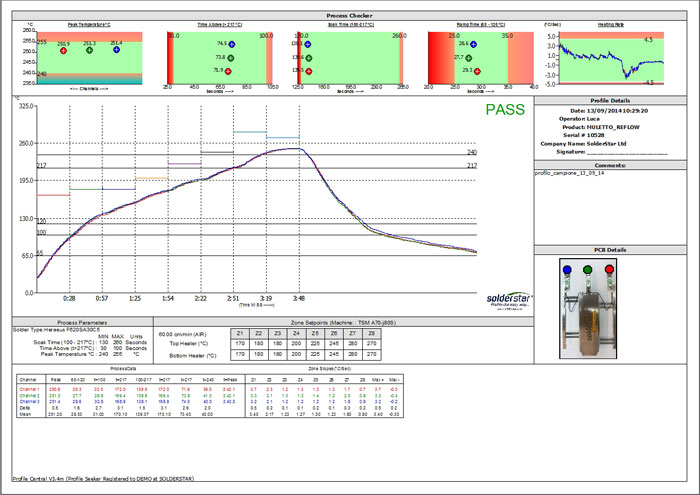

Due to the faster heating rate, the temperature difference in the latter section of the SMA is larger. The solvent volatilization is insufficient, which affects the welding quality. If it is too fast, the thermal shock will occur, and the circuit board and components may be damaged and too slow. The purpose of this area is to heat the PCB at room temperature as soon as possible to achieve the second specific goal, but the heating rate must be controlled within an appropriate range. Temperature setting method of reflow oven preheating section: The reflow oven temperature setting is to set the reflow oven temperature curve.ġ. This is very useful for obtaining the best solderability, avoiding damage to components due to over-temperature, and ensuring soldering quality. The temperature curve provides an intuitive method to analyze the temperature change of a component during the entire reflow soldering process. The reflow oven temperature curve refers to the curve of the temperature of a certain point on the SMA with time when the SMA passes through the reflow oven furnace.

0 kommentar(er)

0 kommentar(er)